History

2022

April/Octobre: Fly screens renewed

In order to keep our HACCP concept on a safe level, we have renewed the fly screens on the windows in the production rooms and the associated storage rooms in departments 1 and 2. In Octobre we were also able to renew the fly screens in Departments 3 and 4 and the associated storage rooms.

We are now fully protected for the 2023 summer season.

2021

May: Efficient and constant compressed air

In order to provide constant pressure during the production process over a longer period of time and to relieve the environment, we have installed 2 new compressors as well as 2 new refrigeration dryers.

These will save up to 15% energy compared to conventional compressors.

2021

March: Successful certification according to test standard ISO 9001:2015.

2020

June: Air conditioning created for production to improve the working conditions of our employees in times of increasingly hot summers.

2020

March: Renovation of the production rooms.

2019

June: To modernise our IT, we renewed our operating system.

2018

June: New bicycle station was built so that our employees can also commute to work in an environmentally friendly and fuel-saving way.

2018

March: Successful certification according to test standard ISO 9001:2015.

2018

March: Exterior facilities renewed and pylons erected in a new light.

2016

November: Pallet racking system set up.

2016

August: Purchase of two fully automatic high-performance lines with computer-controlled monitoring systems.

2016

June: Renovation of the production rooms.

2016

May: Establishing of two cosy cafeterias for our staff.

2016

February: Creation of new office space to optimise the order and accounting system for you.

2015

Modernisation of our production: as of now, digitally via production screens.

2012

October: Purchase of two fully automatic high-performance lines with computer-controlled monitoring systems.

2012

October: Construction of a new hall to expand our capacities for you.

2012

January: New access road created for planned warehouse.

2010

Renovation of our office premises.

2009

Addition of a warehouse to the existing production site.

2008

Production output was increased by 25% by implementing 3 high output lines with computer controlled surveillance systems.

Karl Eschrich GmbH goes online and presents its own website.

Design of the outside facilities, parking area and construction of a bridge connecting new and old production building.

2007

Construction of a new production and warehouse building.

2006

We created the possibility to produce under cleanroom conditions for laboratory and medical purposes.

1993

Mr Karl Andreas Eschrich, grandson of the company founder, takes over the fate of the company. The main action is primarily the renovation and expansion of the plant. Also the machinery is modernized.

1990

The plant is reprivatised.

1972

Machinery and equipment is expropriated and transferred into socialistic production processes. Nevertheless, Mr Edgar Eschrich manages to maintain the status of the sole proprietor of ground and buildings. Moreover, the company has been managed by family members until 1990.

1960

An association of co-operatives takes over the plant’s business relations.

1930

Even in the 1930s and 1940s, company “Dr. August Oetker” has been a main customer of the produced crimp vials.

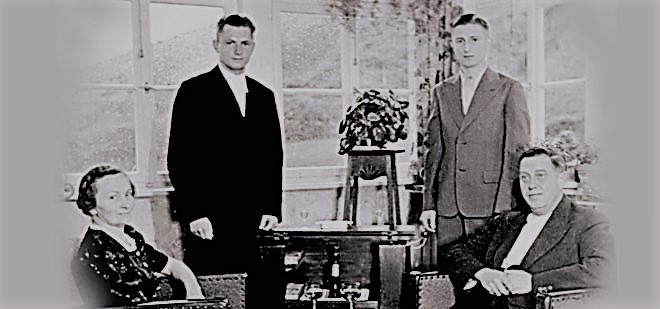

1926 - Foundation

Foundation of the company by the grandfather of today’s owner,

Mr Karl Eschrich.

The picture shows the founding family Karl Eschrich and Rosa Eschrich with their two sons. Otto and Edgar Eschrich to see.

Karl Eschrich founded the company "Karl Eschrich chem.pharm. Glassware Haselbach".